Get the latest news from tracezilla

News in tracezilla this spring

Automatic purchase or production order based on sales

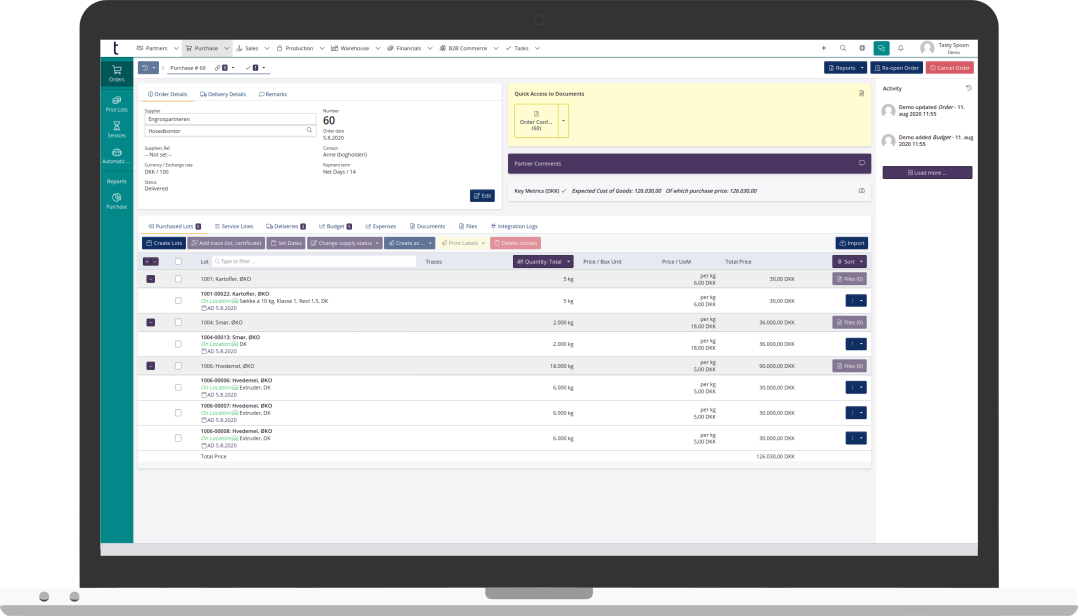

It is now possible to further automate the creation of purchase or production orders based on sales orders.

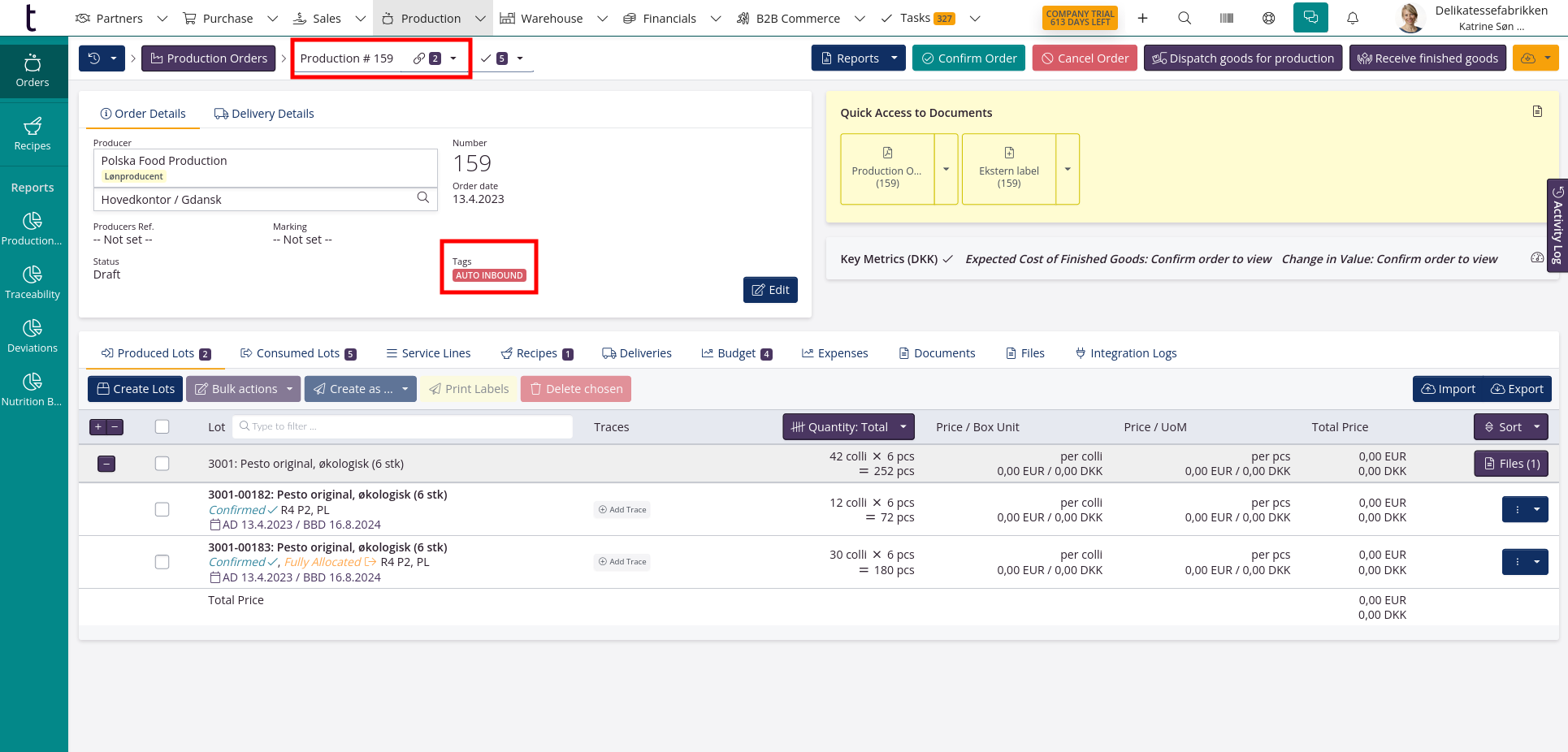

With the new setup, purchase or production orders will be automatically created based on sales orders that are entered manually. The tag ‘Auto inbound’ is added to the incoming order, so it is clear that the order has been created automatically.

In the case of production in several phases, new, incoming production orders will automatically be created on the basis of the created production orders. This can be done back thorugh many productions stages. Production orders can be divided per SKU and per sales order so they are put on individual production orders.

It can be set up so that inbound lots are selected automatically on production orders. For many, however, it will still be important to check the automatically selected lots, so that they are actually the same as the ones used in production.

In cases where the lot selection does not have to be checked - for example if the picking is done by an external supplier - it is possible to set up a flow that closes down production or purchase orders automatically when the sales order has been delivered.

Update of underlying production orders when changing the sales order

When production orders are created based on sales - either by the automated flow described above or by clicking the Confirm sales order with production button - there will now be a closer link between the orders.

If changes are made to the sales order after they are linked, the underlying production order will be updated so that it corresponds to the changes on the sales order.

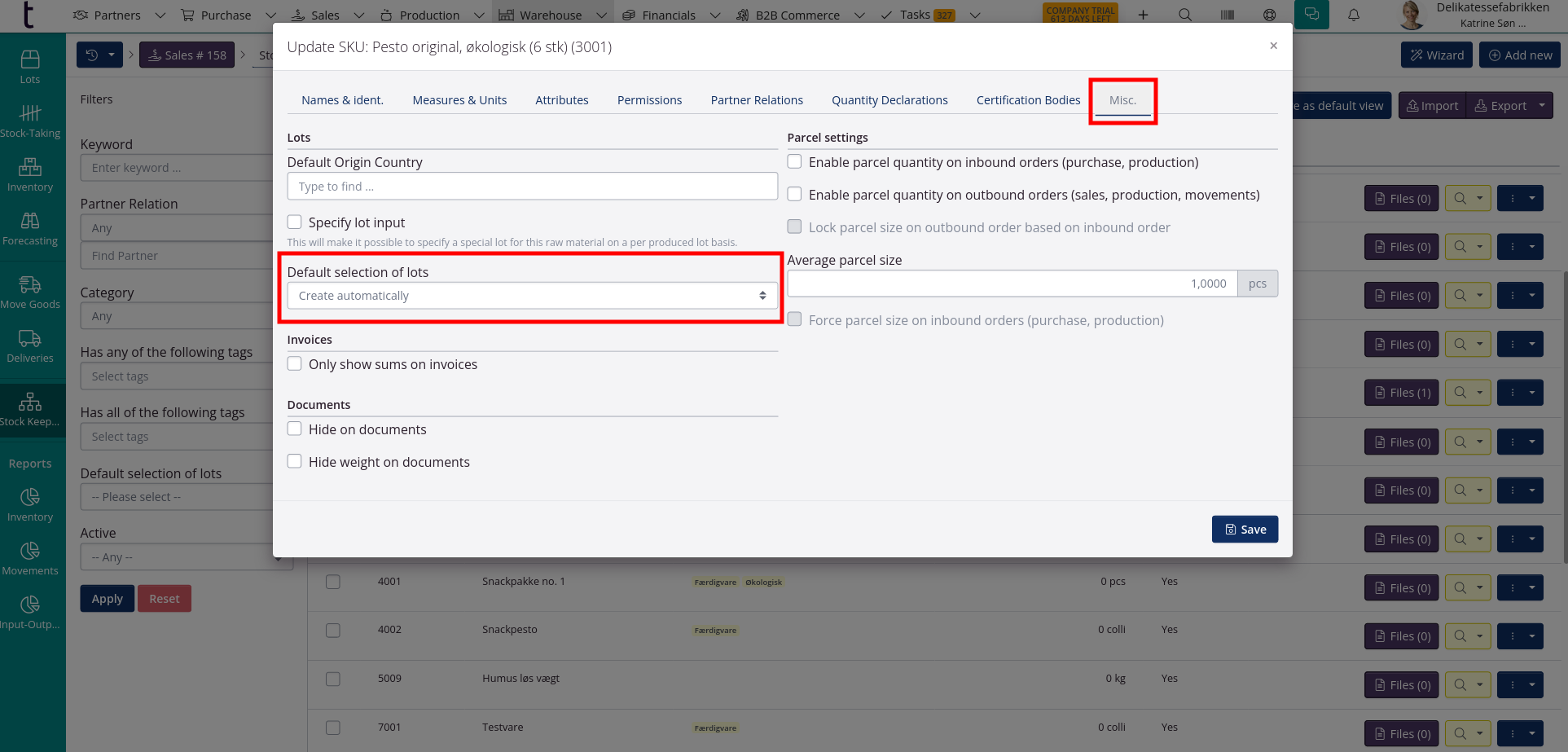

Standard method for selecting lots can be set for each product type

It has long been possible to specify how lots should be selected as a standard for the individual order types.

Now you can set the standard selection of lots for each SKU.

This could be relevant if some SKU’s should be included in an automated flow, where SKU’s are selected automatically, while others are not.

A filter has been added to the left of the SKU list to make it easy to see which item types have which selection method as standard. It is also possible to set the selection method for several SKUS’s at the same time via bulk actions.

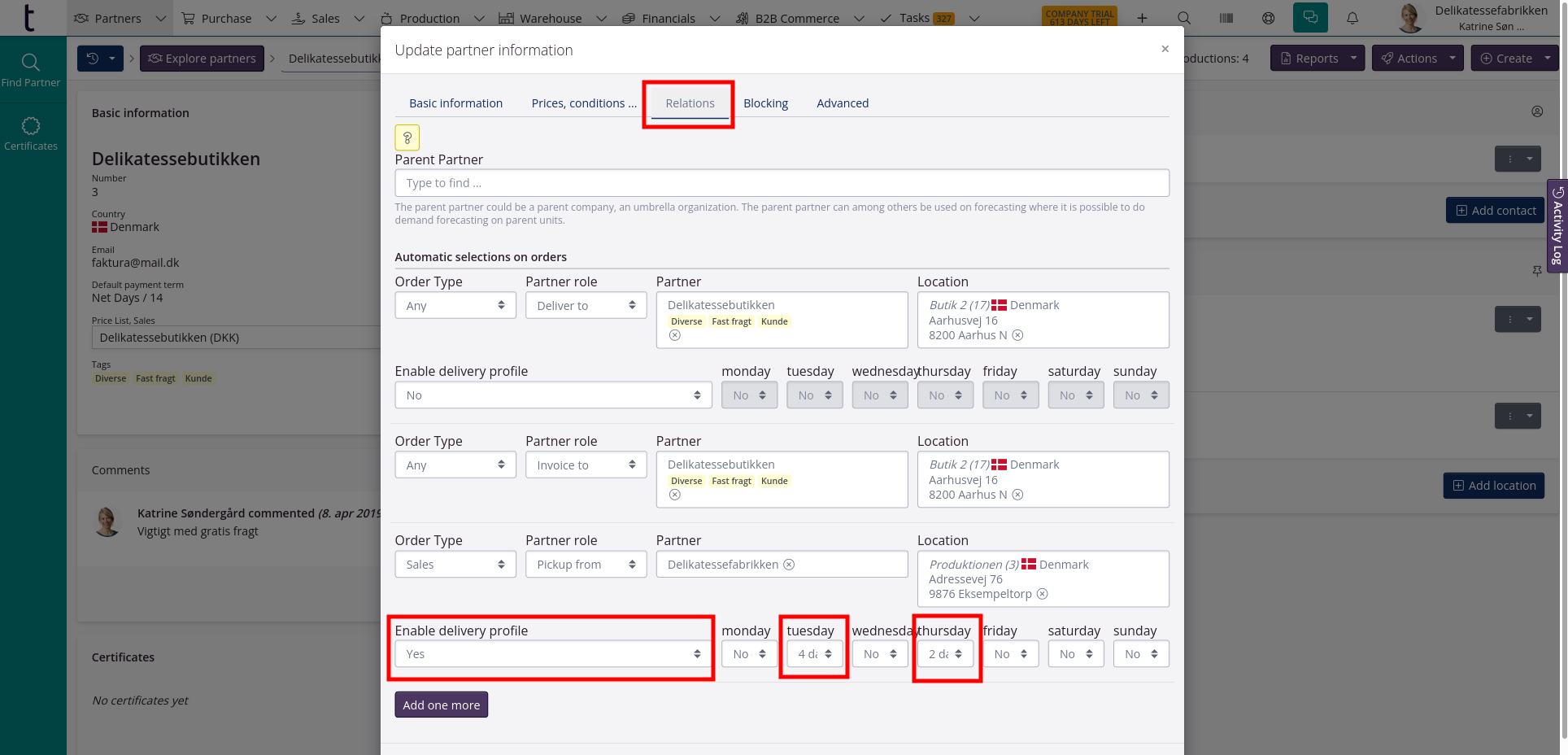

Delivery profiles

It is now possible to enter delivery profiles for customers and suppliers.

It may be relevant if a customer or supplier wants delivery / delivers on certain days of the week. In the delivery profile, you can also specify how many days before the delivery date the pickup date must be set.

The delivery profiles can be used in the automated order flow, in B2B Commerce and when creating orders manually.

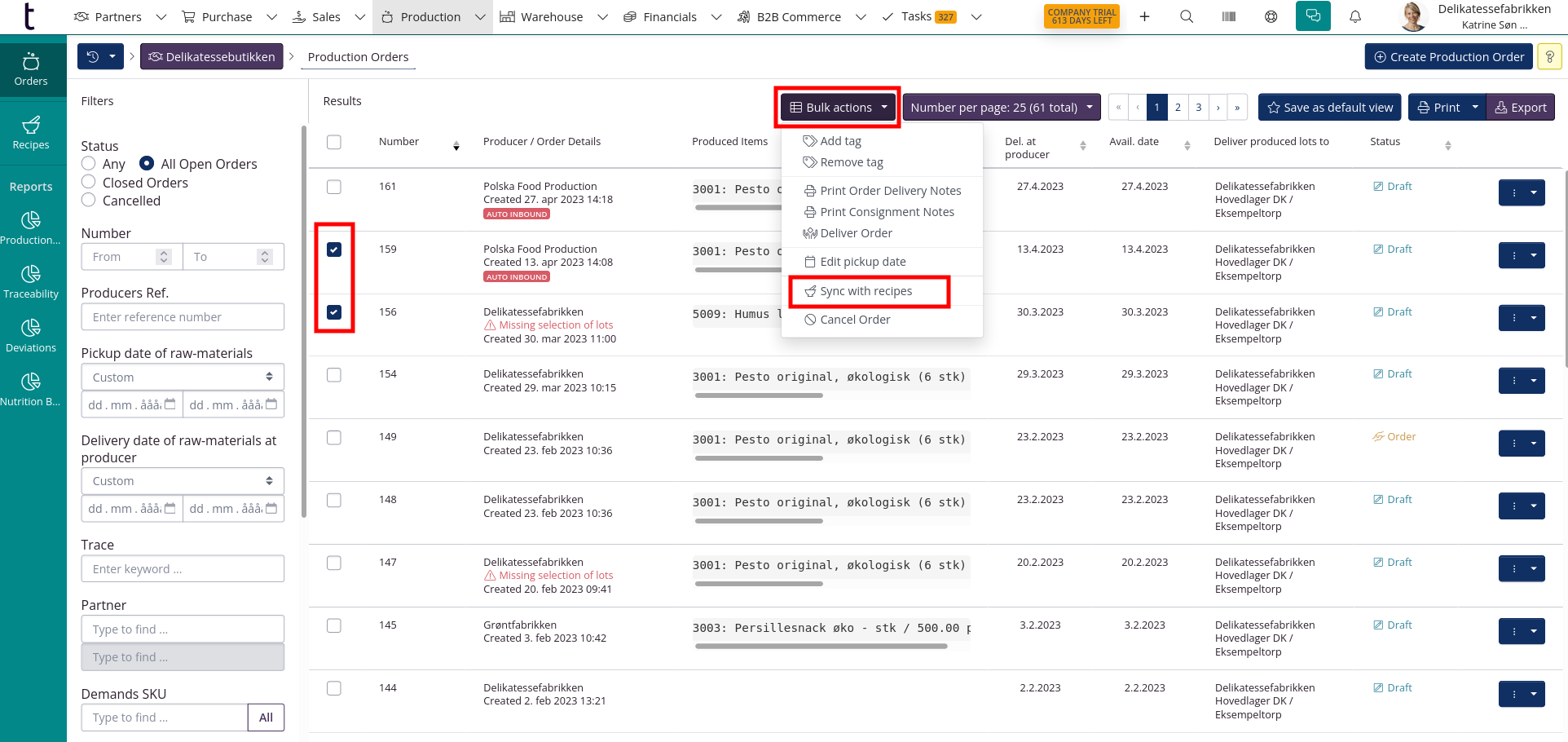

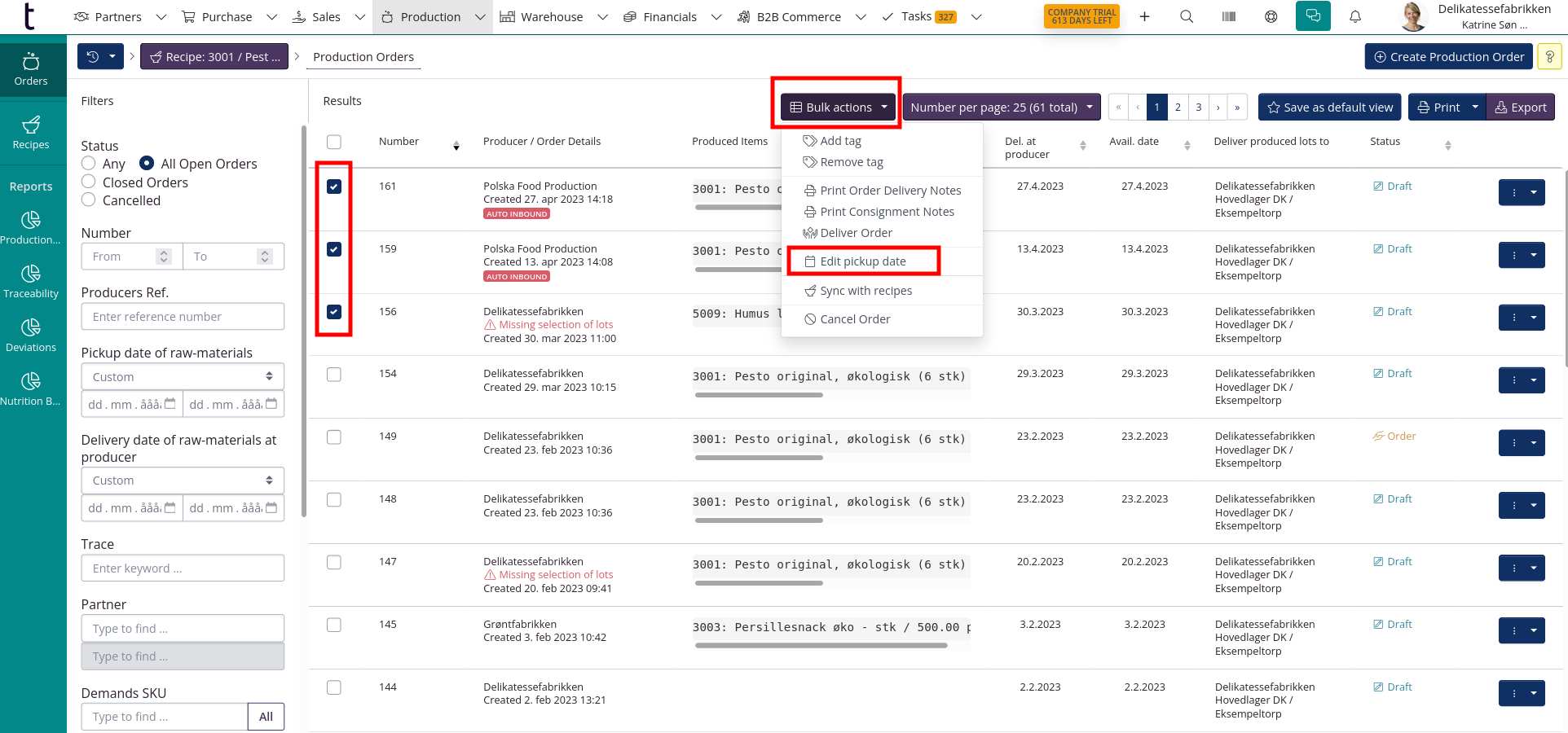

Synchronize production orders with recipes

If changes have been made to the recipes and some created production orders need to be updated with the new customizations, this can now be done easily via bulk actions.

Changes in standard costs on the recipe are also recalculated on the order.

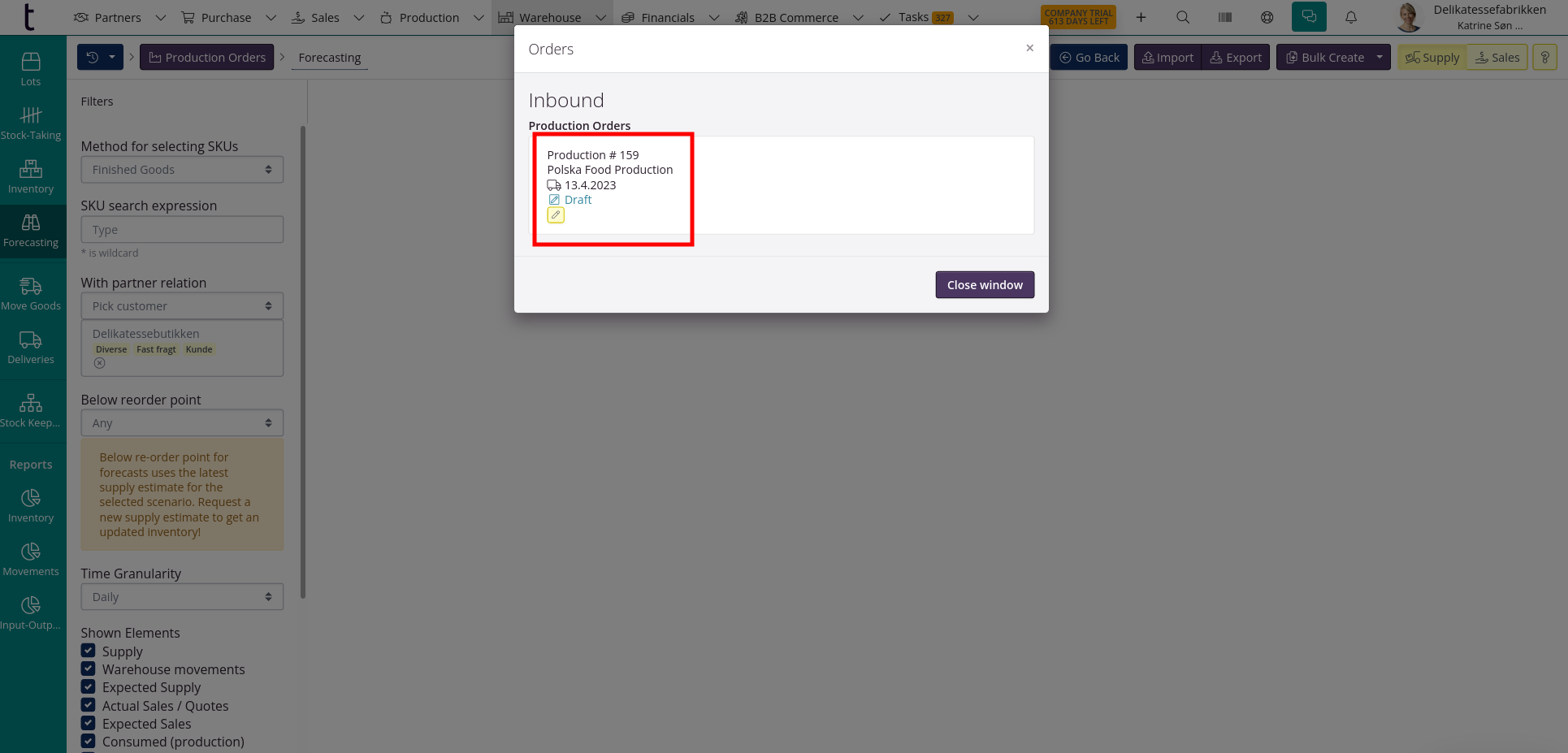

New possibilities in forecasting

Some improvements has been made to the forecasting feature:

-

When mass creating productions via forecasting, tracezilla can now create one production per finished good. This means that the individual products do not all come on the same production order

-

Tags that are available both for SKU’s and for orders are now automatically added to the order when creating the order via forecasting

-

Stock movement is now shown in forecasting if the scenario is limited to a given location

-

Via forecasting, you can now update the number of units produced or purchased on already created orders directly from the forecasting. Only open orders can be edited (screenshot)

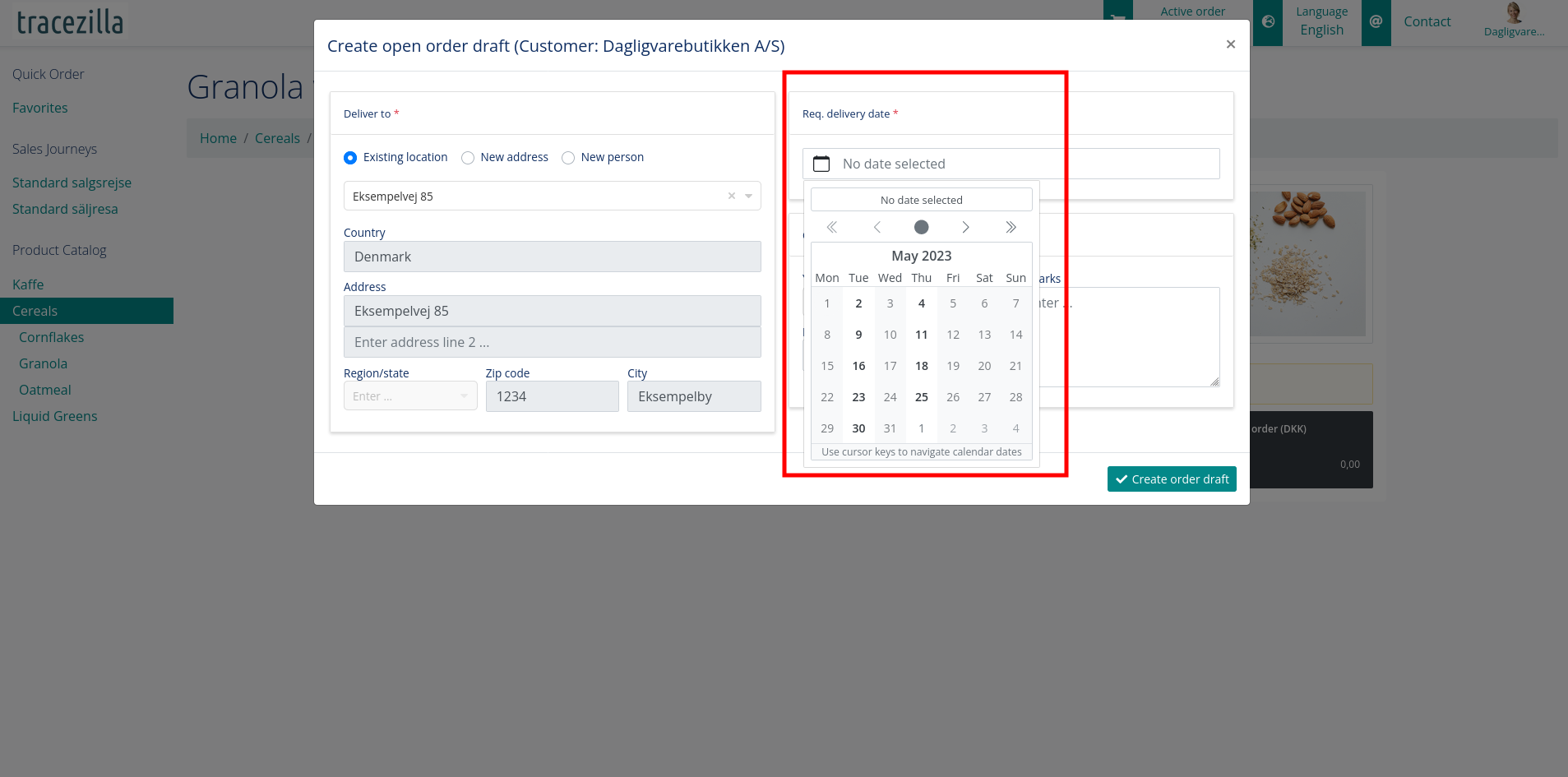

Improvements in B2B Commerce

Some improvements have been made to B2B Commerce - tracezilla’s own sales portal/B2B webshop.

-

It is now possible to specify delivery profiles for customers, so that they only have the option of ordering for delivery on certain weekdays (screenshot).

-

The flow for creating customer locations via B2B Commerce has been improved

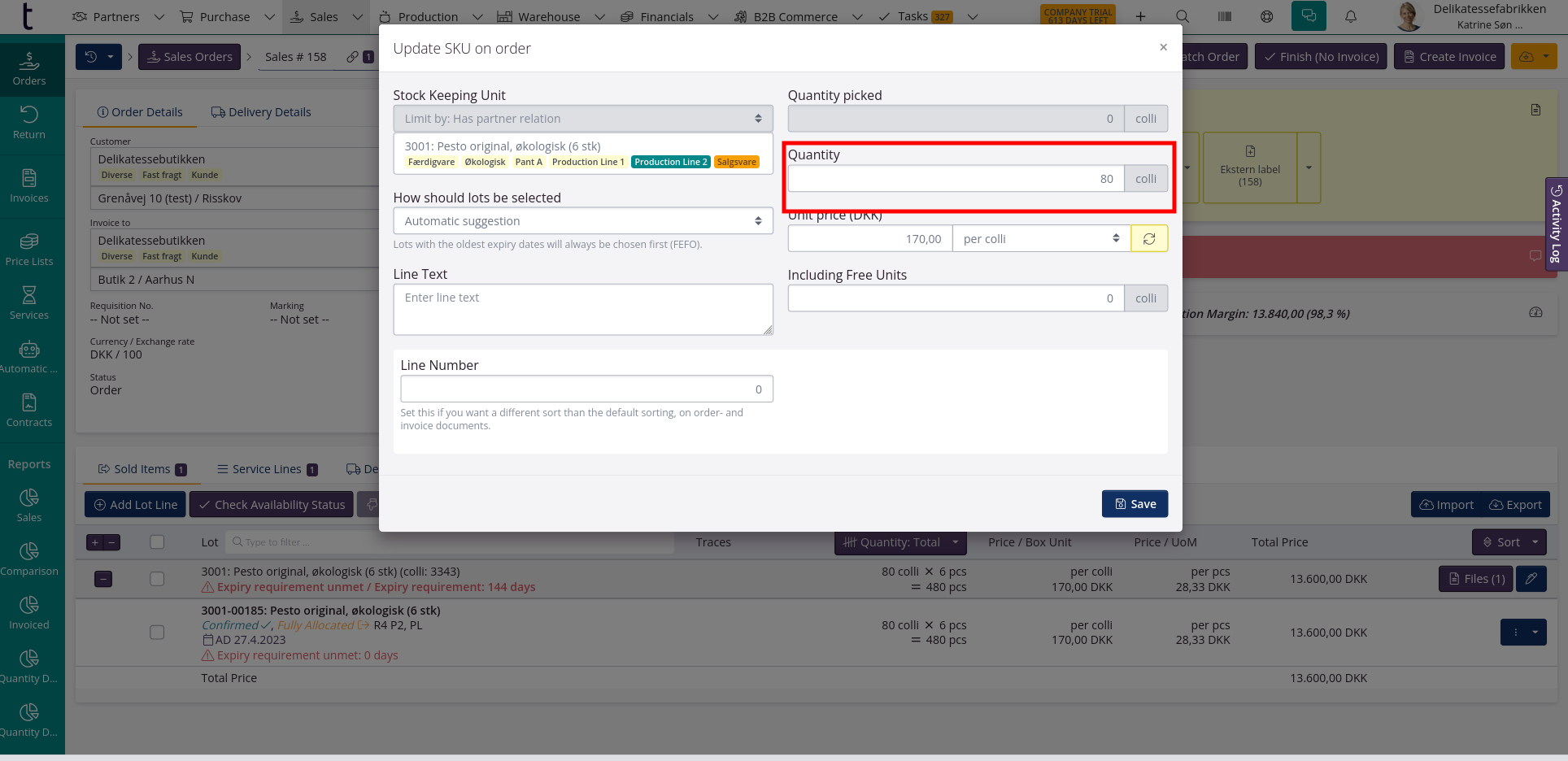

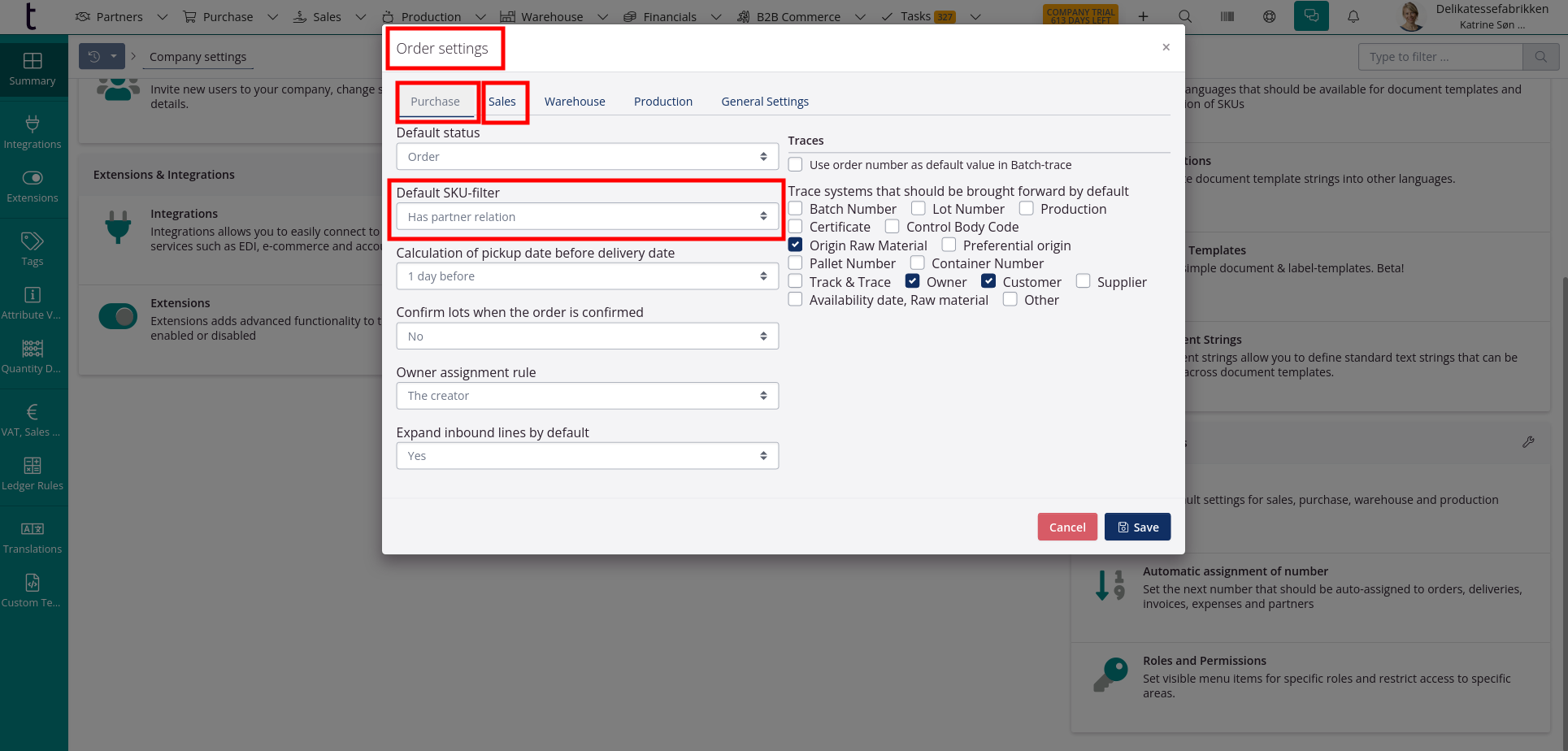

Set standard filter for selection of SKU’s on orders

It is now possible to limit the SKU’s in the dropdown list when adding products to an order by default.

For example, you can choose only to see SKU’s with a partner relation set for the relevant customer or supplier. This limits the number of SKU’s that are displayed when selecting SKU’s on an order.

You can always change the filter on the individual order so that all SKU’s can be added.

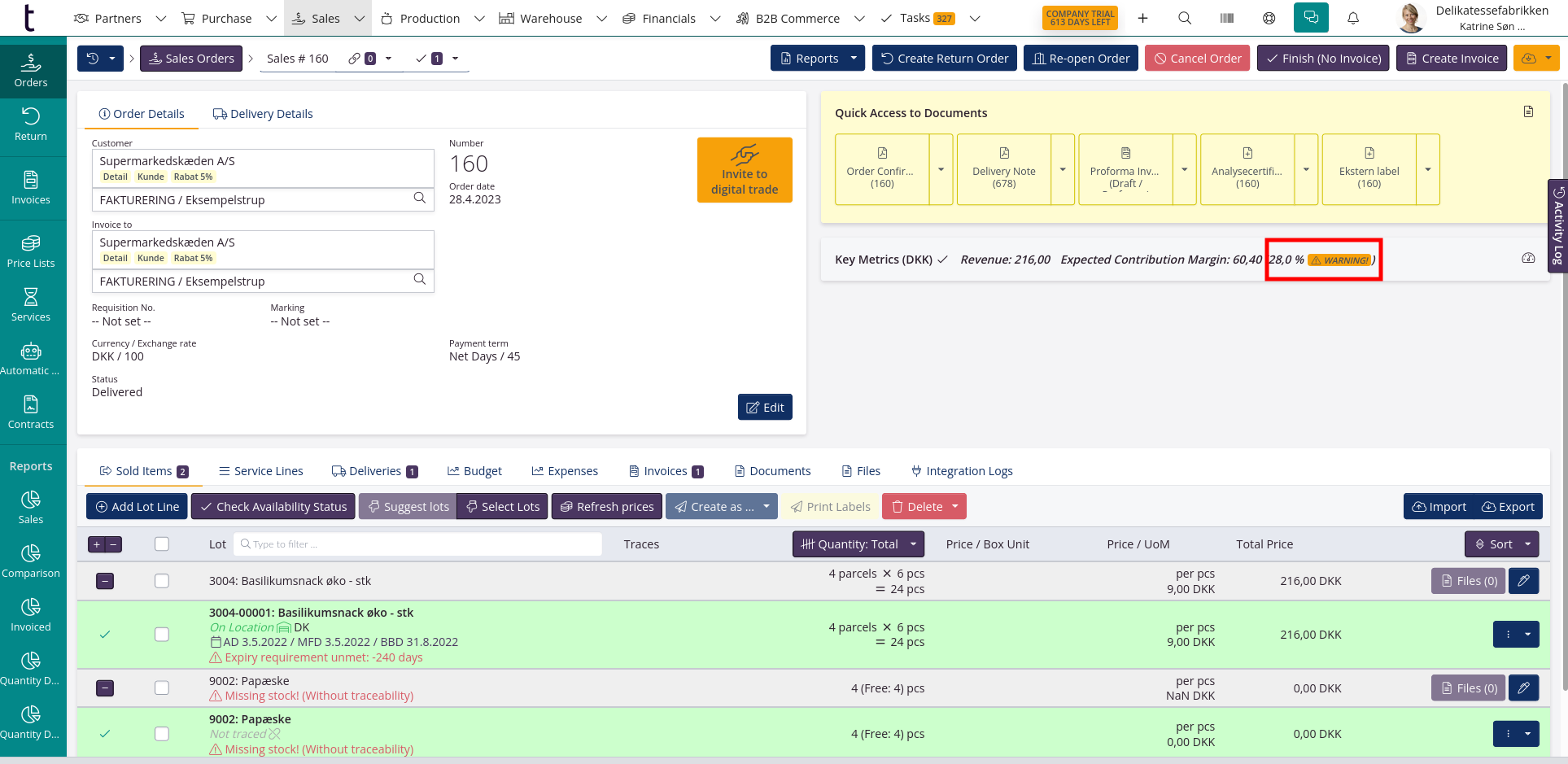

Warning on orders if margin contribution or dividend is not as expected

You can now specify a minimum for what is an acceptable margin for sales orders or an acceptable yield for production orders.

You specify the minimum limit under Company Settings > Order Settings. If the margin or the yield is below the limit, a warning will appear on the order.

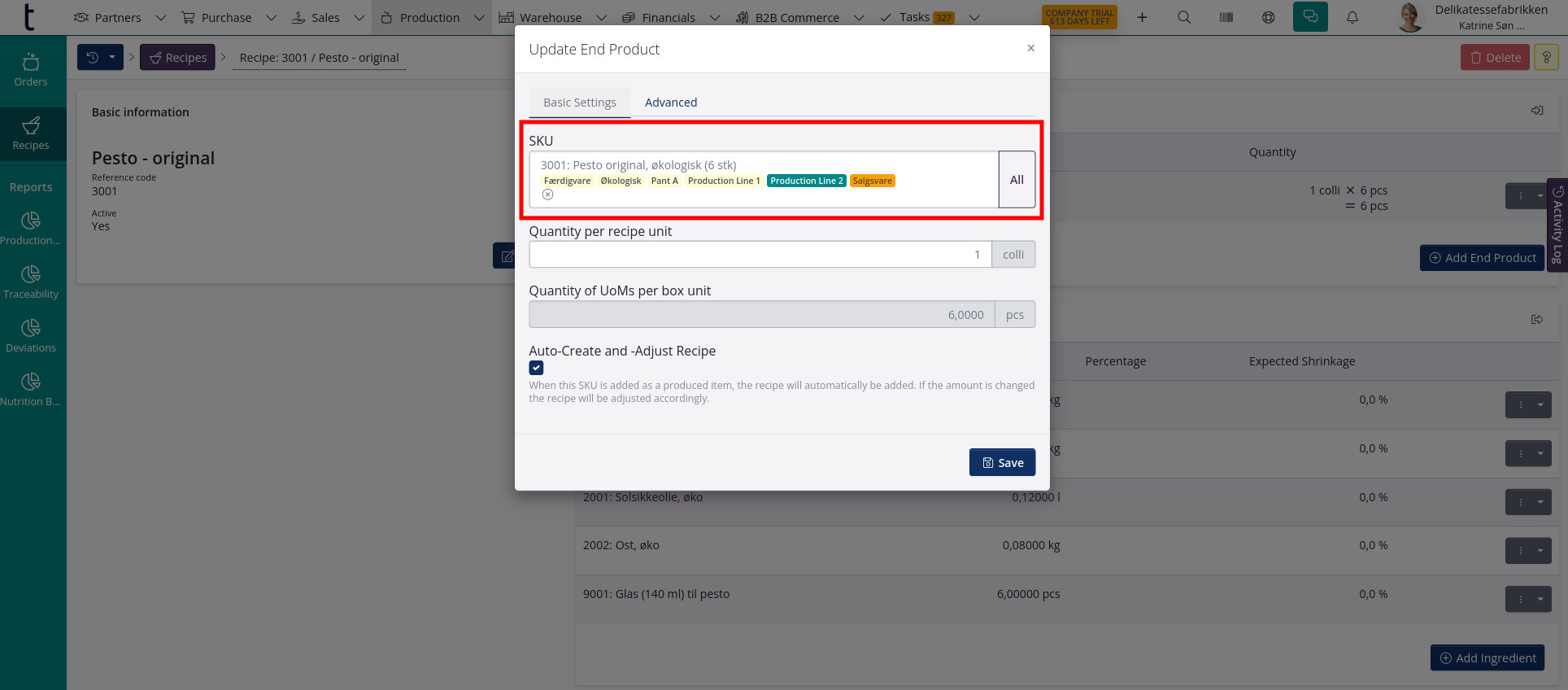

SKU tags appear when lot lines are added to orders and when SKU’s are added to recipes

Now tags for SKU’s are displayed when lot lines are added to orders and when SKU’s are added to recipes. This makes it easier to ensure that the right product is added.

Pickup date on orders can be corrected via Bulk actions

If you have to postpone one or more productions, you can now easily update the pick-up date of the orders via bulk actions. The delivery date is adjusted accordingly on the orders.

The function can be used on purchase, production and sales orders.

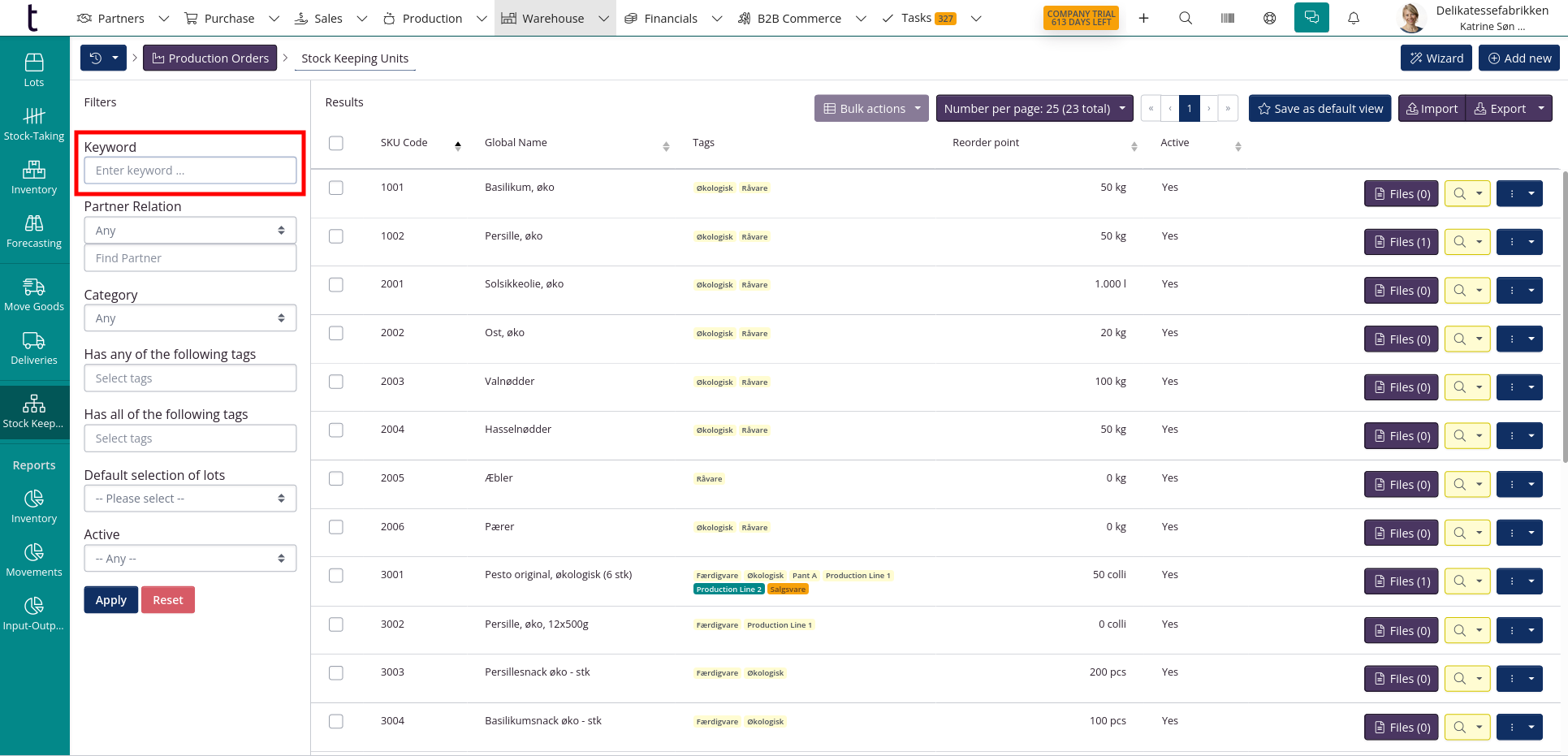

Supplier SKU code included when searching in SKU list and when selecting SKUs on orders

When you search for a SKU using the ‘Keyword’ field in the SKU list, the supplier’s SKU code is also included in the search. It requires that the supplier is listed as a partner relation, that the partner is marked as a supplier and that the supplier SKU code is entered.

If you want to search for a customer’s SKU code, you can use the Partner relation filter and select the customer in the filter. You will then be able to search in the keyword field by the customer’s SKU code.

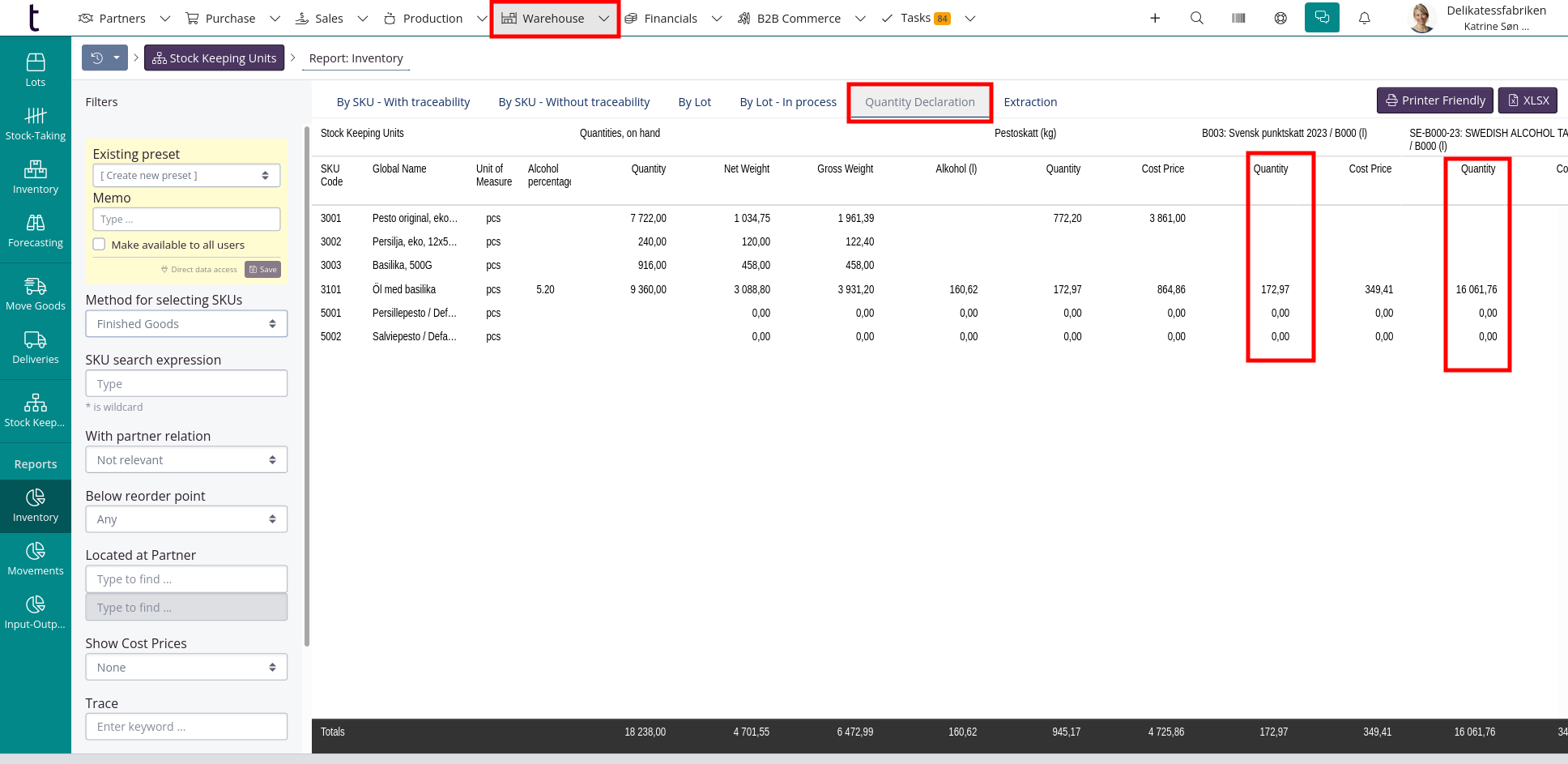

New report on the value of excise duties at a warehouse location

If you need to track the value of excise duties on goods at a given warehouse location, there is now a report for this.

In the ‘Inventory’ report, a tab has been added that shows the value of excise duties on the goods that are physically located at a given warehouse location. The tab is only displayed if you have activated the ‘Quantity declarationm’ extension under Company settings > Extensions.

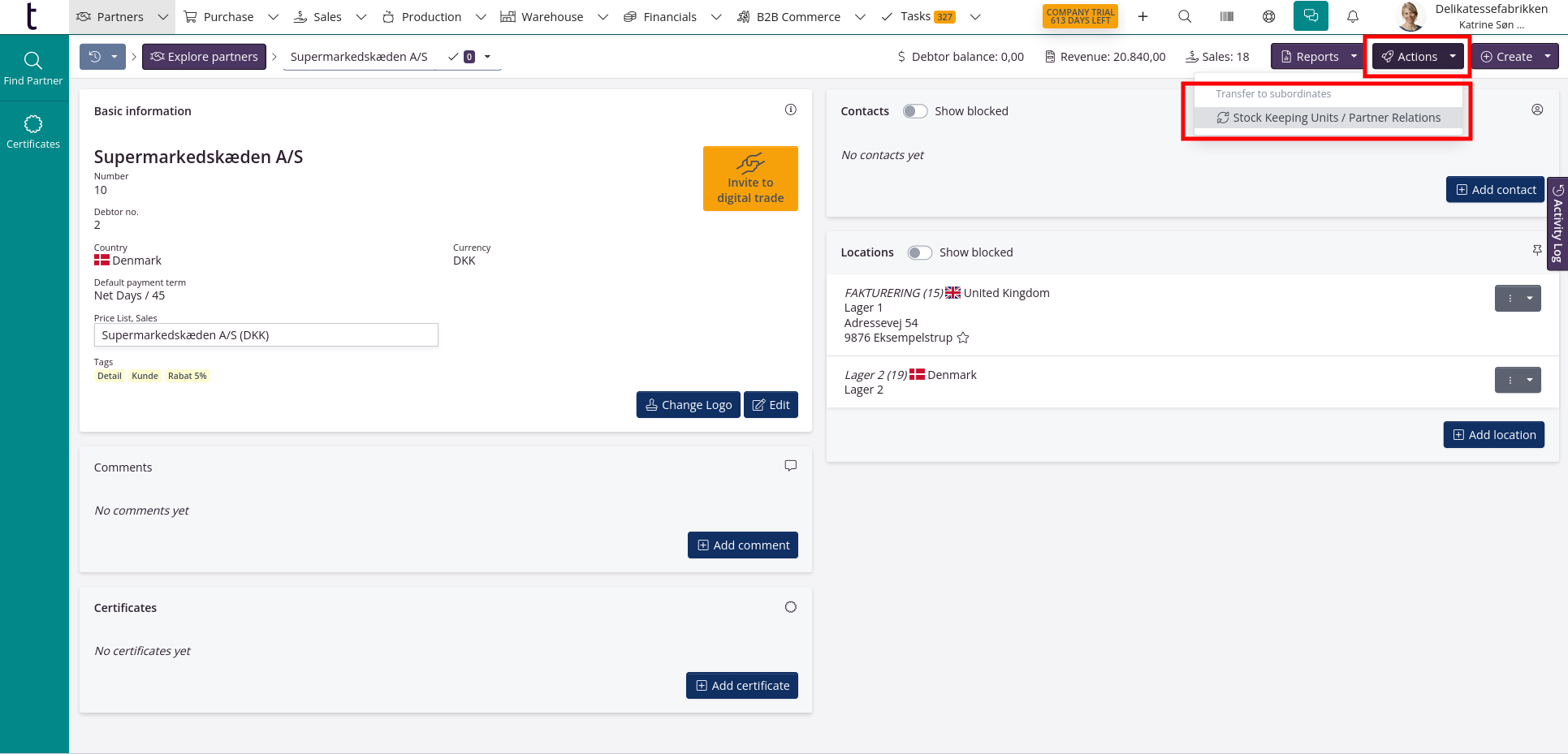

Copy partner relations from a parent partner

If you have customers who are part of a larger organization and who need to be added as partner relation on the same SKU’s, you can copy the partner relations from the parent partner to all the subordinate partners.

The parent partner must be added as ‘Parent partner’ on the individual subordinate partners. This is done under the ‘Relations’ tab on the partner or via mass actions in the overview.

When the parent partner has been added as a parent partner, the ‘Actions’ button will appear on the parent partner. Click and select the option ‘Transfer to subordinates - SKU’s / partner relations’

Receive our newsletter