Get the latest news from tracezilla

News in tracezilla in February

New flow for drop-shipping

Do you send goods directly from your suppliers or manufacturers to the customer based on a sales order? Then tracezilla’s new drop-shipping flow may be relevant for you.

With the new flow, orderscan be created automatically with the relevant supplier(s) and manufacturers based on the goods ordered on the sales order.

The sales order delivery note can be sent as an order document to the supplier/manufacturer directly from the sales order.

The goods on the sales order can come from different suppliers or manufacturers. You just indicate on the SKU who is the supplier or manufacturer of the product. The automatic orders are created based on this.

You can create a socalled delivery profile on you supplier or manufacturer, specifying on which days of the week a given supplier can deliver and how many days oflead time they have. It may be relevant, for example, if a manufacturer has fixed production days. Then the automatic orders will be created to be delivered on that day.

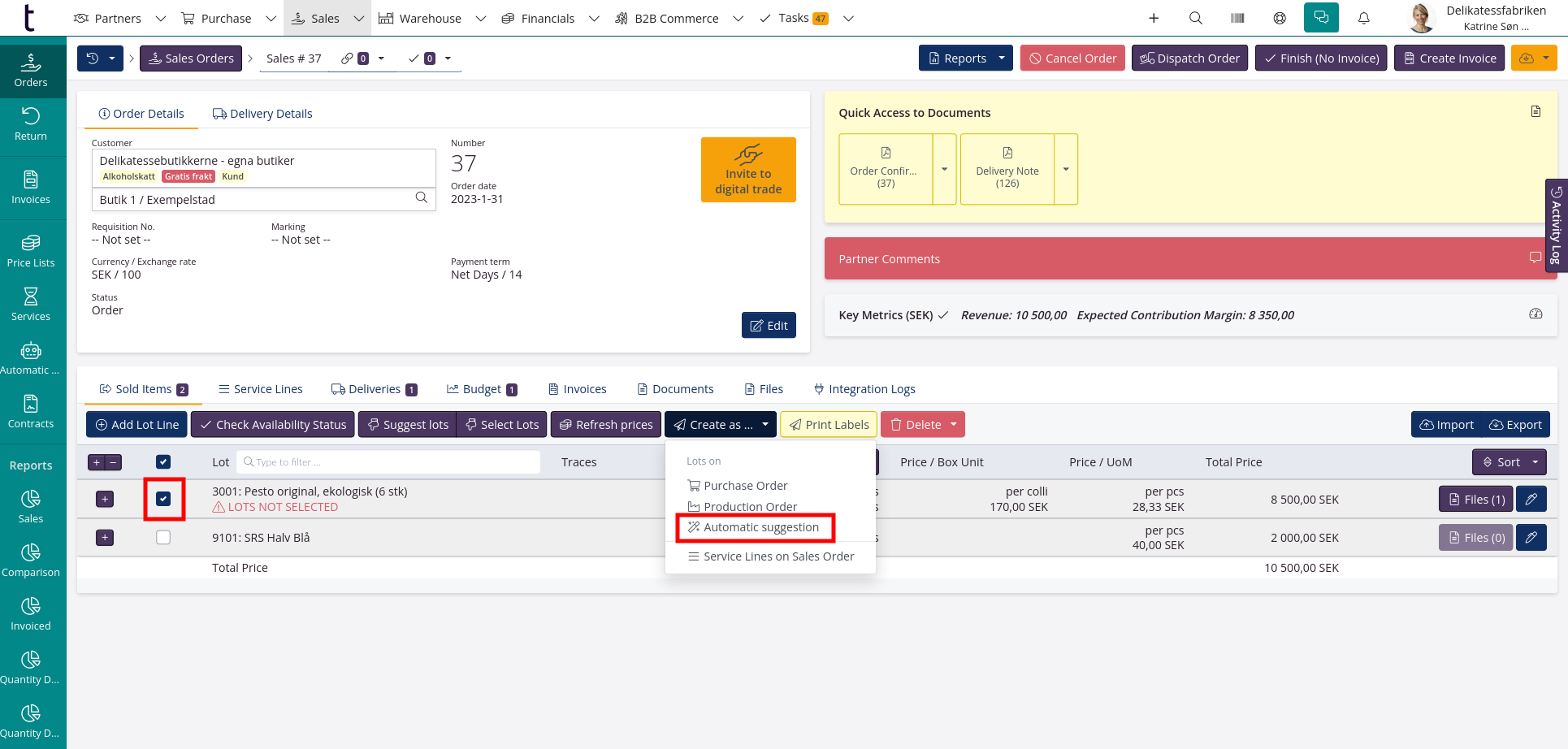

You create the automatic orders by clicking “Create as… Automatic proposal”. The purchase/production orders created will get a tag so that it is clear that they were created automatically.

An order link is created between the orders to make it easy to click back and forth between the orders.

Furthermore, you can specify that a separate production order must be created for each product to be produced.

Updated view of the inventory valuation report

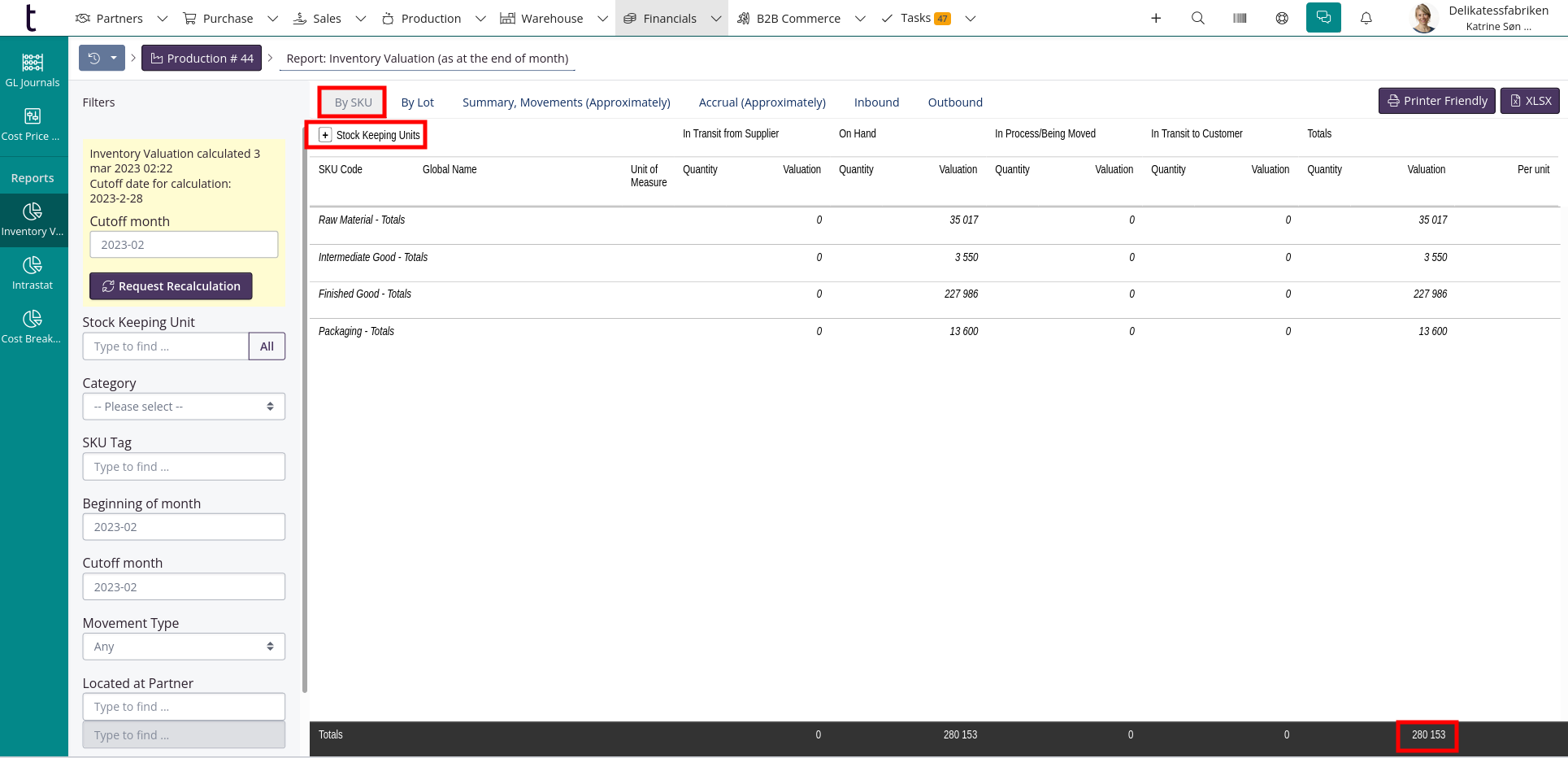

In the inventory valuation report, we have updated the view in the tab called ‘Per SKU’. The inventory value is now summed up per item category using running totals that can be collapsed by item category.

In addition, the users who typically use the cross-sectional calculation method have been given this view on the front page of the inventory value report.

Did you know that…

tracezilla calculates inventory value using two different methods.

-

One is the sum of the value of all product lots in stock and as such is a cross-section of the inventory value. This calculation method is used in the tabs ‘By SKU’ and ‘By lot’

-

The second calculation method adds the value of all incoming goods and subtracts the value of all outgoing goods over time. This calculation method is used in the tabs ‘Summary, movements’ and ‘Accrual’.

There may be a small difference between the two calculations, but if it is too large, it will typically indicate that something is wrong.

Estimate of consumption based on forecast can now be calculated across customers

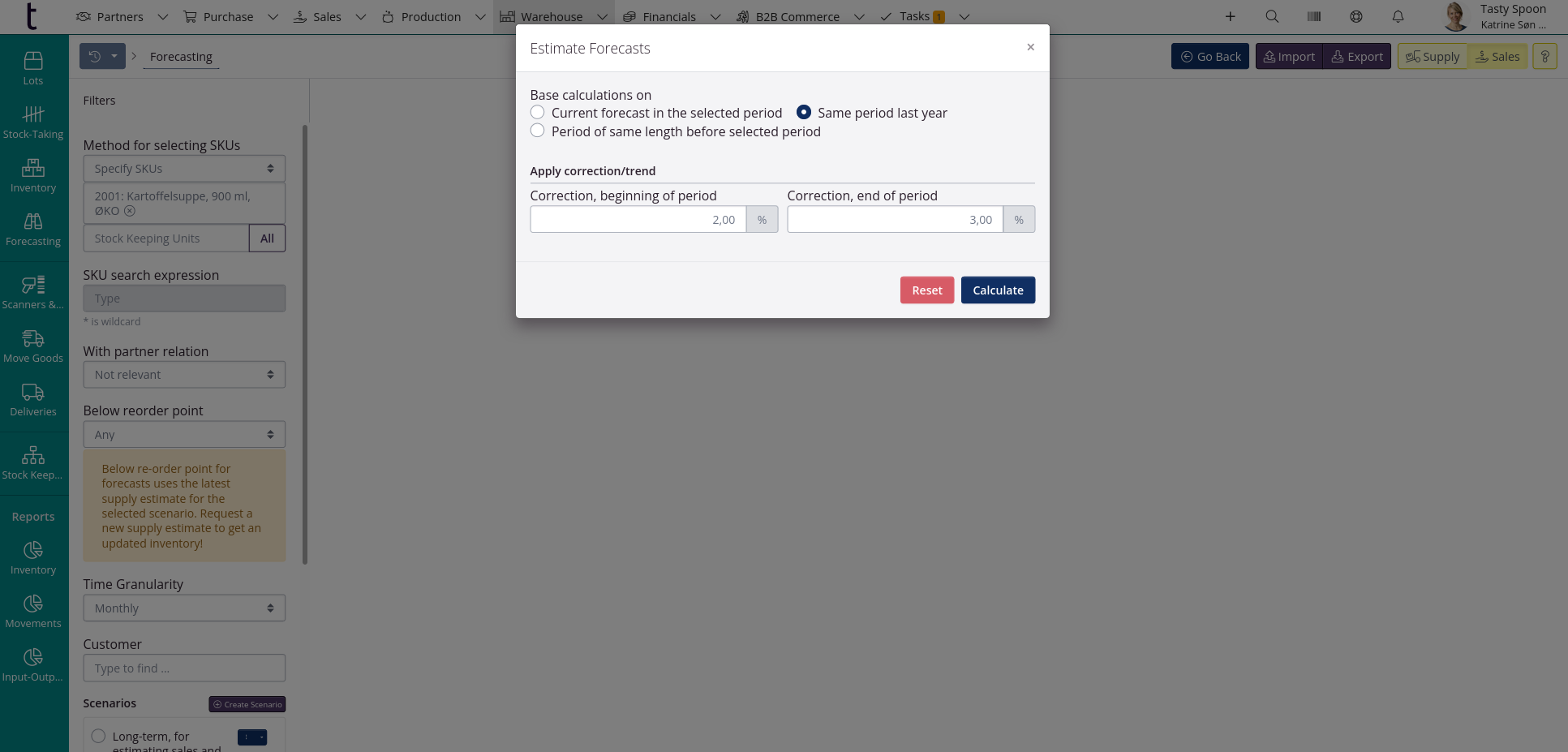

In tracezilla, you can calculate an estimated consumption through several production phases on the basis of a sales forecast.

This was previously possible only on the basis of forecasts for individual customers. It is now possible to make this calculation on general forecasts without specifying the customer.

Read about forecasting here.

Option to send delivery notes to Danish COOP via EDI

You can now send delivery notes to Danish Coop via both of our Danish EDI partners.

Coop require delivery notes via EDI from an increasing number of suppliers.

Read about the integration to B2B Backbone here.

Read about the integration for GS1 Trade Transact here.

EDI via EDI solutions in Sweden

You can get an EDI connection to supermarkets in Sweden via our Swedish EDI partner EDI Solutions.

The flow for receiving orders via EDI can be adapted to the requirements of the individual customers (Coop, ICA, Axfood etc.).

You can receive and invoice orders and send delivery notes via EDI Solutions .

Read about our integration for EDI Solutions here.

Receive our newsletter