Month-end close preparation in tracezilla

When the calendar month changes, many companies carry out stock-taking and inventory valuation.

In the tutorial below, you can read about relevant features for month-end closing in tracezilla.

Stock-taking

It differs from company to company how often the inventory is counted. For some companies it applies that there are written procedures becuase of regulations.

Whether your company does stock-taking monthly, annually or anything in between, we have got some tips for you.

Count the goods as separate lots and register relevant information to distinguish the lots

When you do a status of your inventory, it is important to count each lot separately.

Each lot should have some form of trace or date which enables you to identify the physical lot in real life and in the system. It can be lot number, batch number, production date, best before date or similar.

With the help of traces, you can also distinguish between the lots during the count. Adding dates also helps tracezilla to suggest lots when picking for orders according to the FEFO principle, which helps to ensure a good flow in your inventory.

Count it all at once

Avoid spreading the stock-taking over several days and avoid making purchases, sales and productions on the same day as you do the stock-taking.

It can cause confusion if stock-taking is done over several days, and especially if goods are added to and leave the warehouse during those specific days. In that case, you run the risk of noting some lots as being in stock, which have been picked for e.g. a sales order or double register some lots that have been received on a purchase order. The inventory will appear artificially high, so that you may oversell goods or not discover in time that you are short of supplies.

Register the stock-taking in tracezilla as soon as possible

If too much time passes between the stock-taking place and the inventory status being registered in tracezilla, you may run the risk of having an outdated stock-taking that cannot be used for anything.

Pay attention to note all lots that go in and out of the warehouse after the inventory has been counted, until it is registered in tracezilla.

Remember to note it on a separate sheet so it doesn’t appear to be part of the count - stock movements should be registered on the orders in tracezilla. Otherwise, you may risk a difference in the organic mass balance report, or that the value of the goods is registered as a loss of goods due to stock-taking, or that the cost price of the lot is not registered correctly.

It is recommended that the time between the stock-taking takes place and the registration be as short as possible.

Good practice for stock-taking

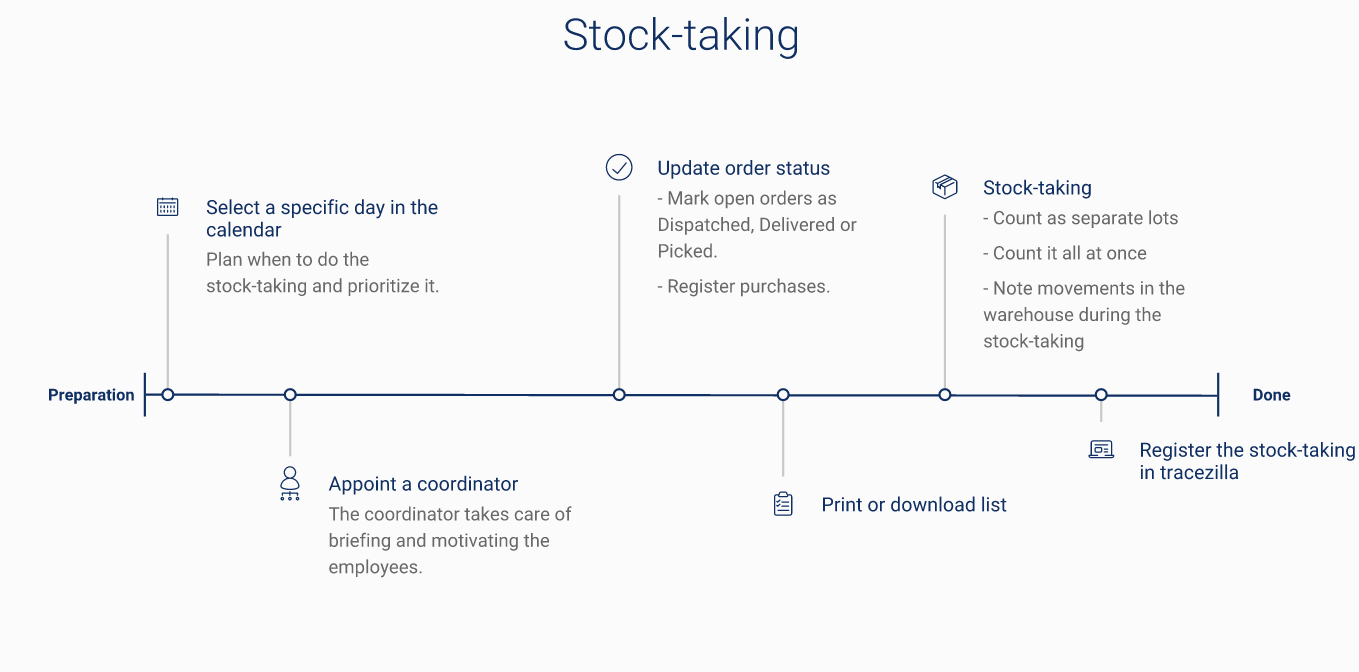

1) Select a specific day in the calendar. It makes it possible to plan with the warehouse which goods will come in and go out from the warehouse that day, so that you avoid mixing up the stock-taking with goods receipt or counting goods that are sent out to a customer on the same day.

2) Involve several employees so that it becomes a team task. By setting aside a day for counting, it frees up resources, as you should avoid producing on the same day as the stock-taking takes place. The count goes faster when several employees help out. In addition, it promotes understanding of the importance of inventory status and valuation when several employees prioritize the task.

3) When there are several people who are helping with the stock-taking, the task must be coordinated. You can point out a coordinator who is responsible for printing the list for the stock-taking and splitting it up, so that two people do not count the same goods - but at the same time ensure that you count every lot/batch. The coordinator takes care of briefing and motivating the employees.

Prepare the stock-taking – download the list

The stock-taking list in tracezilla is based on which lots are registered as in stock.

Be aware of whether goods are in stock at different locations (addresses/warehouses). Remember to apply filter for this before printing the list from tracezilla.

Tip!: you can download the list based on how the warehouse is arranged. If the warehouse is divided into raw materials, finished goods and packaging, you can apply a filter based on category or tags.

Before you get the list for stock-taking in tracezilla, it is important that your orders are up to date. tracezilla’s list is based on what you have physically in stock according to the registrations.

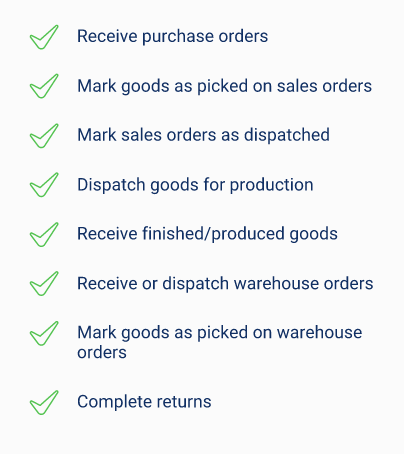

Be sure to update open orders (purchases, sales, warehouse orders, productions) as Dispatched or Delivered to match reality.

If you have forgotten to create and receive a purchase order, the goods will not appear in the stock-taking list.

Goods that have been packed on a pallet for a sales order, but have not yet been sent out, can be marked as picked in the sales order’s delivery-tab.

Read how you do the stock-taking and get the list in this tutorial.

Inventory valuation

tracezilla automatically calculates the value of the inventory based on your stock and each lot’s cost price.

When a stock-taking has taken place, it must be registered in tracezilla, unless the status is registered directly into the application in the stock-taking feature. The calculation of the inventory value runs automatically every night around 3/4/5, so the next day the adjustments (from the stock-taking) will be included in the inventory valuation.

Please note that the inventory valuation follows an accounting period of one month. This means that the effect of the sotck-taking on the inventory value can be seen in the month in which the status is registered, when the month has ended.

Example:

Stock-taking takes place on 30 November.

The stock-taking is registered the day after, i.e. 1 December.

The inventory value is recalculated on the night of 2 December. On December 2, you can see the inventory valuation report after the inventory is updated.

Transfer of inventory valuation adjustments to accounting system

tracezilla has built-in integrations to some accounting systems, so you can transfer posts based on inventory adjustments with a few clicks so that the inventory value is reflected in your accounting system.

Read more about the setup in the tutorials for the individual integration. tracezilla has built-in integrations for Visma e-conomic, Fortnox, Visma eEkonomi, Reviso and Zoho Books.

Read more about the transfer of adjustment posts to e-conomic here.