Traces for traceability

tracezilla keeps track of the traceability of your lots. As the entire application is built around the lot, tracezilla will automatically ensure traceability of the products you process and sell because you have a lot number for each lot, which is printed on all documents. You can choose to have a warehouse without traceability.

To ensure traceability back to your suppliers, and even the suppliers of your supplier, you can add a trace to your lot. This can be the lot number that came with the lot when you purchased it from your supplier.

You can add other traces like container number, pallet number or a certificate from your supplier. Read about certificates.

A trace can be added to a lot or to a delivery.

- You can add the trace to the lot from your order by ticking the box to the left of the lot line and click Add trace.

- You can also add the trace when you view the lot. Go to the tab Traces and click Add trace. You find your lots by clicking Warehouse in the top menu and select Lots in the drop-down menu.

- To add traces to a delivery, go to the delivery and select the tab Traces. You find your deliveries by clicking Deliveries in the top menu.

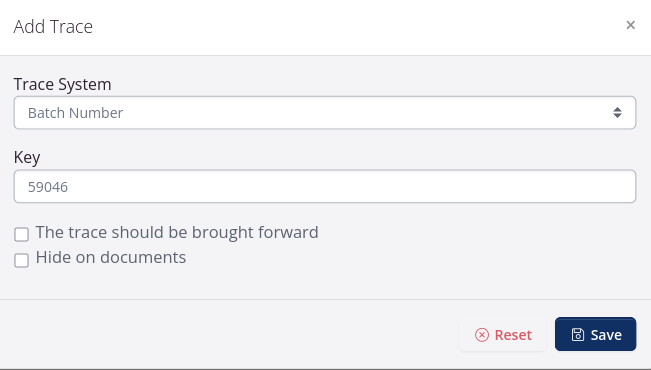

- Click the button Add trace and select the traces system that you want to use. You can select Certificate, Lot number, Pallet number, Container number, or Other. Fill in the number in the field Key.

- If you select Certificate, you must select the certification body amongst your partners. Then select the correct certificat or add the certificate by clicking the +-symbol.

| Trace system | Explanation |

|---|---|

| Traceability | |

| Batch number | You can enter the batch number in the Key field. |

| Lot number | You can enter the lot number in the Key field. |

| Origin | |

| Original Raw Material | If a raw material originates from several countries, e.g. by pooling, the origin can be indicated as country codes according to ISO 3166. |

| Preferential origin | This is the country of which the tariff code was originally asigned. This, according to Commission Implementing Regulation (EU) 2015/2447. |

| Certification | |

| Certificate | You can attach a certificate (it must be created in advance), e.g. organic certificate, to a lot. If you would like to send the certificate e.g. as a PDF, with the order confirmation or invoice, this must be uploaded as a file to the certificate reference, and choose who (supplier, customer, forwarder, producer, warehouse) have access to the certificate. If several products are sold on the same sales order, of which 1 item is certified, it gives greater transparency to associate the certificate reference to the specific lot. |

| Control Body Code | The trace is used to enter the code number for a control body, e.g. NL-BIO-01, BE-BIO-01 etc. |

| Delivery | |

| Pallet Number | In the Key field, enter the pallet number, e.g. SSCC number. |

| Container Number | In the Key field, enter the container number according to ISO 6346. |

| Track & Trace | In order for your customers to track and trace a shipment, you can enter the tracking number to a delivery, if your forwarder/distributor provides the service. Enter the name of the forwarder in the field Label. Enter the tracking number in the Key field. |

| Partner | |

| Owner | The trace is for internal use and will not appear on documents. The trace is linked to a specific partner and is used when a lot has been send from a specific customer. It is used, for example, in upcycling. |

| Customer | The trace is for internal use and will not appear on documents. The trace is linked to a specific partner and is used when a lot is purchased for a specific customer. |

| Other | |

| Other | This is not a tracking system, but allows you to define your own trace. Enter the name or the type of trace in the field Label. Enter the unique code/numeric value in the field Key. |

About the trace systems

A trace is searchable in the lot overview. Click Warehouse in the top menu and then Lots in the drop-down menu, and overview of what is in stock (and has previously been in stock, if Yes is selected for the filter Show empty lots) will appear. Here, you can use the field Trace on the left side to search for the trace.

Be careful with bringing traces forward, as it can impair the traceability

You can tick the box The trace should be brought forward when you add a trace, e.g. a batch number, but for some companies, transfer of the trace from raw material to finished good will not improve traceability.

Few companies will need to use this feature. It may be relevant to your company, and can contribute to easier searching, better overview and good traceability. If your company works with food production, bringing traces forward from raw materials to finished products will often be associated with impaired traceability.

The reason is that it “muddies” your traceability information. It makes it harder for you to identify the individual batch of goods, use search functions and reports, and takes up a lot of space on documents.

It makes sense to use the feature for companies…

- that work with circular products, e.g. textile recycling, where the supplier of the raw material is also the customer of the processed material.

- that rent out machines (e.g. coffee machines) and the serial number must be kept in place after the machine has been moved from your warehouse to the customer’s warehouse, who is lending the machine.

- that repackage fruit or vegetables, where the original trace from the supplier of the bulk product must be used on the packaged product, and the label will be provided with this trace.

The feature should not be used if…

- a trace is added to raw materials or semi-finished products in manufacturing food companies, where, for example, 10 ingredients are included in a production.

Then the 10 traces will be transferred to the final product of the production, which will thereby have 11 or more traces associated with it. In the event of a recall or withdrawal it will be difficult to identify the specific batch of goods that is problematic, as there may easily be 30+ search results that appear when searching using a particular trace.

In addition, the traces will cause stock-taking lists, picking lists and other documents to become unnecessarily long when the traces are listed per line. The overviews in tracezilla will also become much longer, so that fewer search results can be seen on the screen at the same time.

Regardless, traceability is intact

Every time a product is produced or purchased, a lot is automatically created (SKUs without traceability excluded). tracezilla automatically assigns a lot number to all lots.

Traceability is kept under control with this unique lot number, which makes it possible to create a traceability report. The report provides an overview of all related lots backwards and forwards in the supply chain. This means that you can always retrieve a full report during a recall, withdrawal, inspection visit or audit, without the need to bring traces forward for any traces you add yourself.

When the traces of the raw materials are only on the raw materials, it also becomes easier to identify the correct raw material that needs to be traced if your supplier, for example, contacts you with a recall. When searching for a specific batch number, only one search result (the source) will appear, which makes it possible to create a traceability report that identifies all other relevant batches.